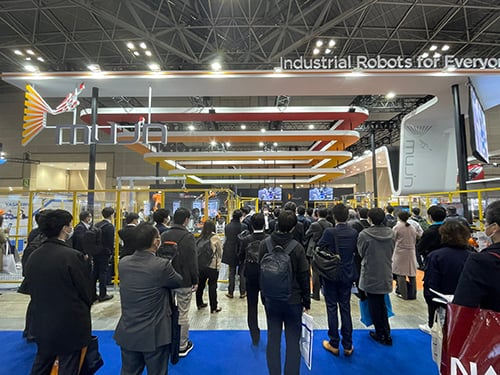

News briefs for the week take a look at what’s happening with cobots at the International Robot Exhibition 2023 in Tokyo, called simply IREX. The convergence of cobots with genAI is continuing briskly. Many cobots, the important ones (over 30 specialized cobot manufacturers are sporting nearly 125 cobot models) are now racing to acquire genAI capabilities. IREX was a perfect event to showcase the best and to see what has happened so far.

Cobots showcase “new-age” tech at IREX

The recently concluded IREX International Robot Exhibition 2023 (Tokyo) 29 November to 2 December 2023, with over 600 exhibitors and 120,000 visitors—reportedly larger than both Munich’s AUTOMATICA and Detroit’s Automate—proved to be a perfect global showcase for cobots’ new-age technologies.

Evolved or new-age cobots were on display from Techman, Dobot, Elite, UR, AUBO, and more.

Announced just prior to the doors opening was a first-ever marketing and sales effort directed solely at SMEs (Small to Medium Enterprises) by the Robot Industrial Basic Technology Collaborative Innovation Partnership or ROBOCIP. ROBOCIP, a group including major Japanese robotics and automation companies, “announced that it is creating a first-ever joint database to facilitate the introduction of robots and cobots to small and medium-sized enterprises (SMEs).”

Japan needs new business in a hurry! Japanese robot makers are feeling competitive heat from across the Sea of Japan. “The global  market share of Japanese robot manufacturers has declined from 70 percent at its peak to about 40 percent due to the rise of Chinese competitors.”

market share of Japanese robot manufacturers has declined from 70 percent at its peak to about 40 percent due to the rise of Chinese competitors.”

Then too, maybe the recently announced initiative also directed at SMEs by the Softbank/ Symbotic Green Box joint venture was the impetus for ROBOCIP. Green Box will address the more than $500 billion annual “warehouse-as-a-service market,” especially targeting the wider customer universe of SMEs.

Also, with the massive China Industry Robot Exhibition (CIRE) upcoming in Tianjin from 6 to 9 March 2024, ROBOCIP had the four days of IREX to make a case for itself in the media with both potential buyers and sellers of Japanese robots and cobots.

With Japan’s largest robot vendor, FANUC, taking its first financial decline in four years, FANUC’s net profit for the July to September period fell 20 percent to around $222 million.

“The slowdown in China’s economy is cutting into the profits of Japanese companies like FANUC. Among 17 Japanese companies with significant sales in China, 12 saw net profit decline in the July to September quarter.”

In the U.S., the “slow US economy and high-interest rates are being blamed for a 37 percent drop in the number of industrial robots ordered in North America from April to July 2023, compared to the same period in 2022.”

A recent Stanford University report showing that 77 percent of all robot and cobot sales go to just five states (all in the automaker belt) have seemingly tanked along with slow auto sales. With the low-hanging fruit from automaker sales drying up, some robot and cobot vendors are finally looking to SMEs to fill their order books.

With Japan’s 3.58 million SMEs making up 99.7 percent of Japan’s companies, ROBOCIP will make a concerted effort to attract them to robot-driven automation, which is much needed reports a recent government white paper. Among Japan’s millions of SMEs low productivity hampers the economic growth of the nation, cites the paper.

A similar study directed at the U.S. and conducted by MIT’s Susanne Berger found a similar low productivity rate among SMEs in U.S. manufacturing.

In both Japan and the U.S. the remedy for SME low productivity was obvious: automation. For Japan, the introduction of ROBOCIP is thus very timely.

Notable cobots at IREX

The winds of genAI (generative artificial intelligence) are racing through the robotics industry, and every tradeshow seems to bear witness to the sea change taking place in robots and cobots. The new tech is not just fancy accessories for robots and cobots, they are must-haves to compete, to be more productive, and to succeed at digital automation.

Tokyo’s IREX was a perfect opportunity for vendors to put on display how they have converged their robot and cobot lines with new-age technology. Techman (Taiwan), Dobot (China), Elite (China), Universal Robot (Denmark), AUBO (China), and more showed up. All of which fits perfectly with the IREX show theme: “Sustainable Society Brought by Robotics”.

Techman, is an apt example of how the cobot industry has been trending since the advent of the genAI era. Going forward, a cobot can’t be just a simple cobot any longer. Much more is expected of them, which is a timely evolution of cobot capabilities anyway.

Techman, a subsidiary of Taiwan’s Quanta, followed others in getting beefier with a 25kg payload and 1,902 mm reach, but also brainier, with its TM AI Cobot S Series across industrial applications (notice the AI in the product name). Techman has teamed up with NVIDIA’s Isaac Sim to simulate, test and optimize its cobots as digital twins while using NVIDIA AI and GPUs for training. Plus, using NVIDIA’s Metropolis vision AI framework, Techman is now enabled for AOI (automated optical inspection). Even on parent Quanta’s  own electronics assembly lines, Techman with AOI is perfect for optimizing inspection workflows. Inspecting products ranging from auto parts to circuit boards, the Techman’s vision AI can quickly identify defects.

own electronics assembly lines, Techman with AOI is perfect for optimizing inspection workflows. Inspecting products ranging from auto parts to circuit boards, the Techman’s vision AI can quickly identify defects.

So, whether closely inspecting electronics, tending a CNC machine, picking from mixed pieces to sort and pack, or palletizing anything from 3kg to 25kg, new-age cobots are flexible and smart enough to do almost any job. Expectations for cobots are sky high, and if they cannot perform, they are gone! Cobots can’t just lounge around any longer unchanged. Today they are on a high-tech treadmill that’s ramping up the ease and speed of getting things done in a hurry.

See NVIDIA video below for a good look at new-age cobots at work.

As part of the trend to get more brawn into its cobots Dobot showcased its newly-launched CRA series, which comprises 7 robot models with payloads from 3 kg to 20 kg and working radii from 620 mm to 1,700 mm. As an example, Dobot had its new CR20A palletizing solution with 20 kg payload and 1700 mm reach on display.

On the brainier side of things was AMMR (Autonomous Mobile Manipulator Robot), “capable of unrestricted mobility and integrating  SLAM, laser navigation, and human-machine interaction for transportation and pick-and-place, featuring precision navigation, proactive safety measures, and easy-to-use software for safe collaborations.” Dobot said that the CRA series redefines cobots and opens up new paths in the areas of heavy-duty sorting, packaging, and welding in industries such as automotive, household appliances, logistics, and metalworking.”

SLAM, laser navigation, and human-machine interaction for transportation and pick-and-place, featuring precision navigation, proactive safety measures, and easy-to-use software for safe collaborations.” Dobot said that the CRA series redefines cobots and opens up new paths in the areas of heavy-duty sorting, packaging, and welding in industries such as automotive, household appliances, logistics, and metalworking.”

As the Boston Consulting Group has forecast, from here to 2030, robots and cobots will be defined by mobility and intelligence…and shape the future.

China’s cobot JAKA was in residence with a display of versatility. JAKA had 20 of its cobots hosting at 20 vendor manufacturer booths. The 20 red and silver cobots were difficult to miss in the sea of robots on the show floor.