Take a look at the latest news in robotics for the week as we delve into the details of CES2024 and its decreased number of robots but increased focus on AI. Additionally, Doosan Robotics made an early entry into the AI-infused cobot market for 2024. Cobots for 2024 are pursuing the “final solution” in the hunt for perfect palletizing in a projected $2.2 billion global market. ABB Robotics has ventured into logistics and home building with its robots, while a small North Carolina entrepreneur is constructing complete homes with the use of factory robots.

CES2024: Few cobots, lots of AI

CES2024, as noted by the Wall Street Journal, appeared to have shifted its focus to an auto show with an abundance of gadgets, leading to a waning influence in the tech industry. Multiple showrooms featured autonomous farm robots and concept drones for future urban travel. Notably, every exhibitor booth showcased some form of integrated artificial intelligence (AI) with their products, drawing in attendees with a spark of interest.

Complementing the prevalence of AI, CES2024 hosted over 30 panel discussions centered on AI, GenAI, and machine learning (ML) and their impact on various business segments.

Complementing the prevalence of AI, CES2024 hosted over 30 panel discussions centered on AI, GenAI, and machine learning (ML) and their impact on various business segments.

Doosan Robotics, having gone public last October, capitalized on the showcasing of its AI-enabled cobot ecosystem, highlighting the Otto Matic, a palletizing solution designed to handle unstructured and random-sized boxes. Doosan’s advanced line of AI-enabled cobots aims to tackle labor-intensive tasks across various industries and offers the flexibility to adapt to new object types, making it a more versatile system.

As for cobots in 2024, the search for perfect palletizing solutions remains a major focus, with Doosan and other industry players striving for success in this area.

Cobots: In hot pursuit of pallets

Cobots have evolved to offer larger payload capacities and longer reaches, making them ideal for palletizing alongside workers or handling mixed-load pallets. Efforts are underway to address the challenge of mixed-load pallets, with Doosan among those claiming to have made significant advancements in this area.

Cobots have evolved to offer larger payload capacities and longer reaches, making them ideal for palletizing alongside workers or handling mixed-load pallets. Efforts are underway to address the challenge of mixed-load pallets, with Doosan among those claiming to have made significant advancements in this area.

Sophisticated sensors and programming within cobot cells enhance the efficient arrangement of products on pallets, which has the potential to streamline logistical processes and material handling procedures in various industrial settings.

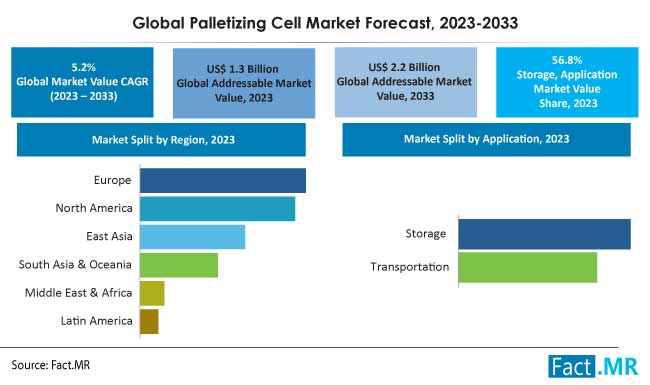

The potential growth of the palletizing machine market is expected to reach $2.2 billion by 2030, representing a significant development in the industry.

A partial adaptation from: https://blog.robotiq.com/whats-new-in-robotics-19.01.2024